MÁQUINA DE CORTE GMT 30 PARA TUBO CORRUGADO

Spagnolo

Immagine:

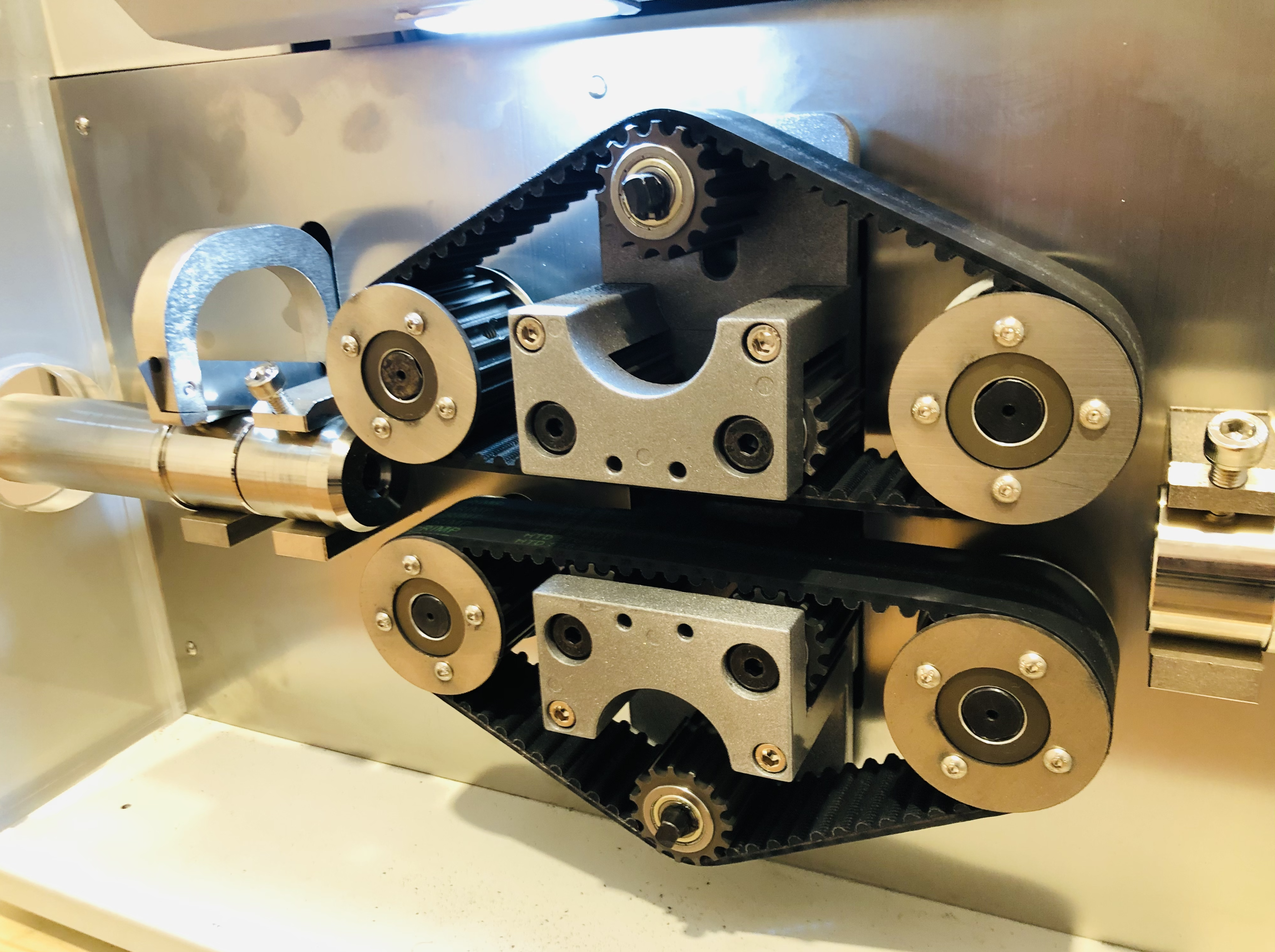

La MÁQUINA DE CORTE GMT 30 PARA TUBO CORRUGADO es una máquina electrónica automática para CORTE DE TUBO CORRUGADO con predeterminación de las piezas en el centro del display y resolución de las medidas en milímetros.

Es una máquina ideal para CORTE DE TUBOS CORRUGADOS con diámetros desde 5 ÷ 30 mm a medida.

La MÁQUINA DE CORTE GMT 30 PARA TUBO CORRUGADO es extremadamente compacta y de fácil manejo, garantiza cortes precisos y alta producción.

La MÁQUINA DE CORTE GMT 30 PARA TUBO CORRUGADO dispone de un accionamiento mediante correas, fácilmente regulables en velocidad y presión de funcionamiento sobre el material, que permite arrastrar el material de forma óptima, asegurando una alta precisión en las longitudes de corte programadas.

La MÁQUINA DE CORTE GMT 30 PARA TUBO CORRUGADO tiene una hoja fina que permite precisión y sencillez en la ejecución del corte. Una cuchilla giratoria adicional, también ajustable, permite realizar un corte a lo largo del eje longitudinal del material, no presente en la versión básica de la máquina.

La MÁQUINA DE CORTE GMT 30 PARA TUBO CORRUGADO se suministra completa con protectores de seguridad, dispositivos de prevención de accidentes, manual de instrucciones y tiene la marca CE.

Technical features:

| ALIMENTATION | Monophase 230 V 50/60 Hz |

| PNEUMATIC ALIMENTATION | 6 Bar |

| ABSORBMENT | 250 W |

| CUTTING LENGTH | 0,1 mm÷100 m |

| WORKABLE SECTIONS | Till to 30 mm |

| CUTTING HEIGHT | Till to 30 mm |

| CUTTING WIDHT | Till to 30 mm |

| FEEDING | 2 Belts Feeding/6 Driver Motors |

| WORKABLE CABLE | Corrugated Tube |

| PRODUCTIVITY | L = 100 mm, 3.000 – 4.000 pcs/h |

| TOLERANCE | <= 0,002 xL (L=Cutting Length) |

| DISPLAY | Touch Screen LCD Liquid Cristal Display |

| MEMORY | 100 Programs |

| WEIGHT | 70 Kg |

| DIMENSIONS | 540x560x570 (WxDxH) |

IN ADDITION TO THE SALE OF THE EQUIPMENT GM AUTOMAZIONI IS ABLE TO PROVIDE MANY SERVICES, INCLUDING:

- WIDE RANGE OF PRODUCTS FROM OUR PRODUCTION AND THE BEST BRANDS ON THE MARKET

- CUSTOMIZATION OF EQUIPMENT AND PLANTS TAILORED TO THE CUSTOMER'S NEEDS

- DESIGN AND REALIZATION OF SPECIAL SYSTEMS

- TECHNICAL ASSISTANCE AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- SPARE PARTS FOR ALL MACHINES OFFERED

- COURSES AND DEMONSTRATIONS TO USE THE EQUIPMENT BETTER

- INSTALLATION AND TRAINING OF THE STAFF EMPLOYED BY THE MACHINES

- VERIFICATION OF FEASIBILITY ACCORDING TO CUSTOMER REQUESTS

- FREE SAMPLES BY TESTING DIRECTLY ON YOUR SAMPLES

- DEMONSTRATION OF THE EQUIPMENT AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- COURSES AND SEMINARS FOR IN-DEPTH INFORMATION ON THE USE OF EQUIPMENT

- SCHEDULED MAINTENANCE TO AVOID EXPENSIVE MACHINE STOP

- POSSIBILITY OF EXCHANGE: THE OLD SYSTEM CHANGES WITH A NEW AND MORE COMPETITIVE

- WE ARE SUPPLIERS OF STEEL, HARD METAL AND TITANIUM STRIPPING BLADES, MINI-APPLICATION CRIMPERS, ELECTRIC TERMINALS, PRE-INSULATED CONNECTORS, SPLICE STRIP

- WITHDRAWAL AND OVERVALUATION OF USED

- SALE OF COMPONENTS AND ACCESSORIES OF THE MAJOR BRANDS OPERATING ON THE MARKET

- POSSIBILITY TO IMPLEMENT OR MODIFY YOUR OLD PRODUCTION PLANT FOR YOUR NEW MARKET NEEDS

Categoria prodotto:

Immagine 2:

Immagine 3: