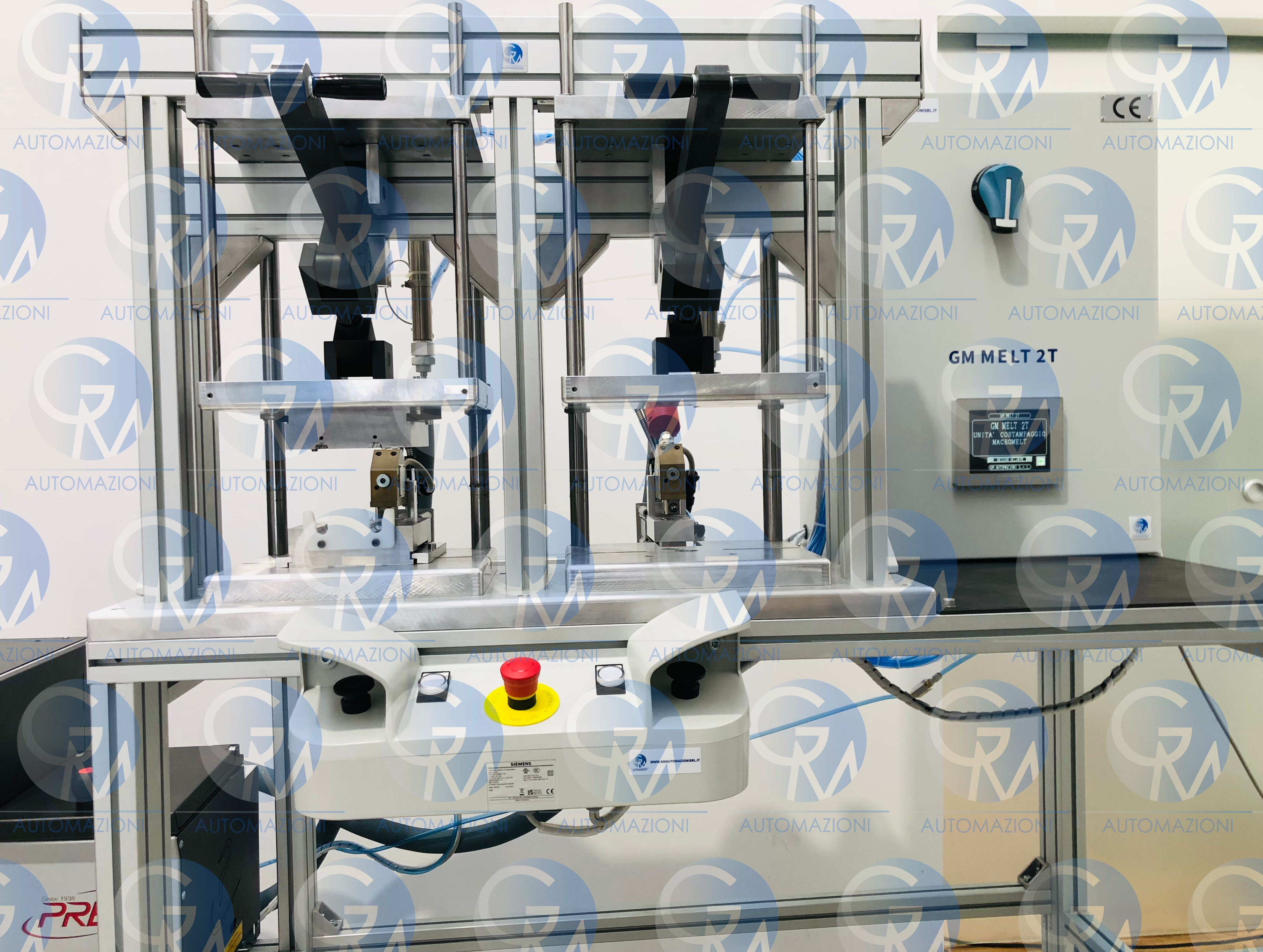

SISTEMA DE PRENSA DE MOLDEO A DIE CASTING GM MELT 2T

El SISTEMA DE PRENSA DE MOLDEO A DIE CASTING GM MELT 2T es una máquina de comoldeo de inyección horizontal de dos cabezales para la producción de co-moldes ergonómicos de resina monocomponente (melt) con control automático programable por PLC.

Permite imprimir conectores y tapones de material plástico para lograr el procesamiento requerido por el cliente a través de los moldes hechos a la medida

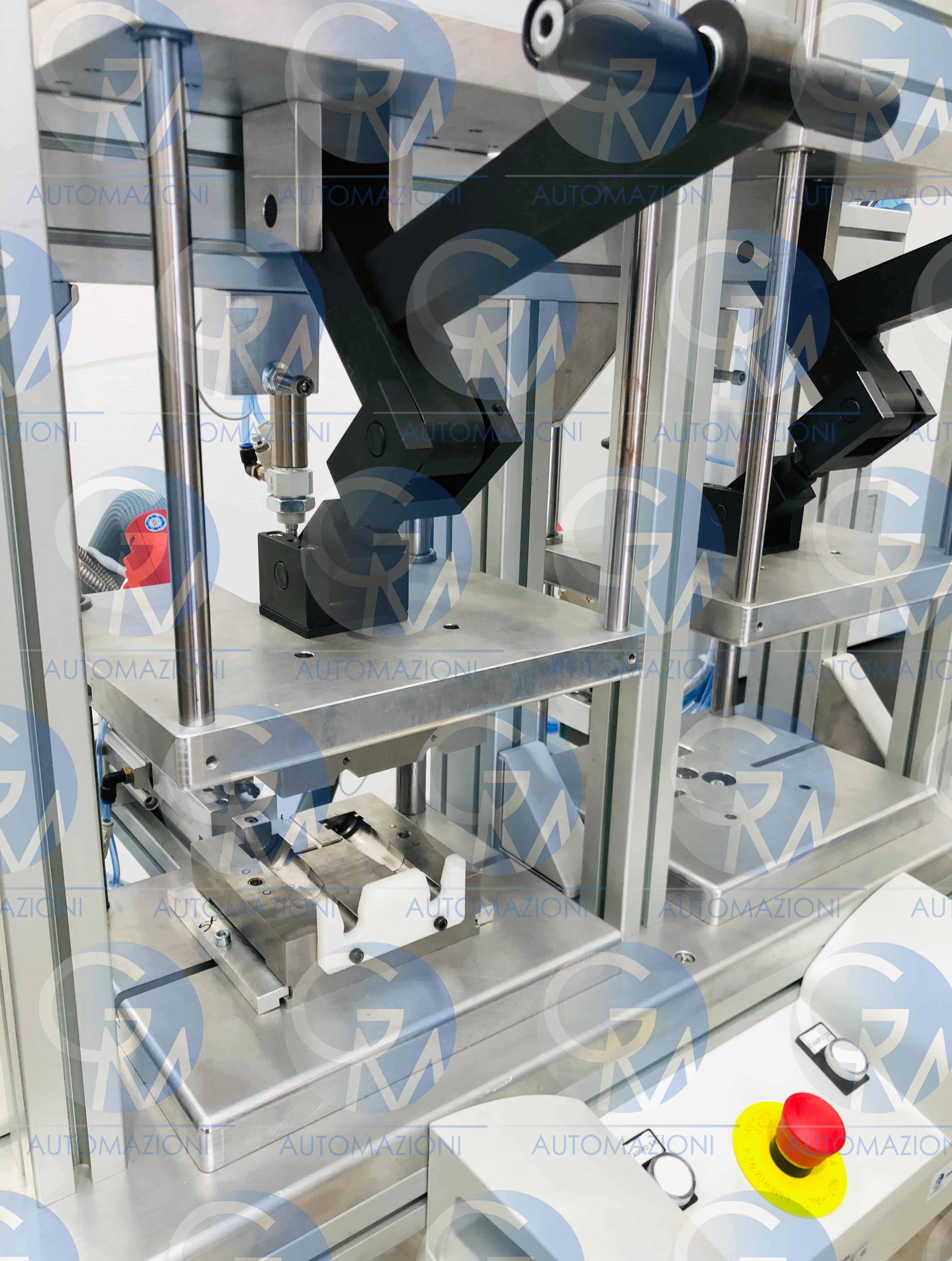

El SISTEMA DE PRENSA DE MOLDEO A DIE CASTING GM MELT 2T tiene una estructura de perfil de aluminio completa con fusor de 4 litros, 2 pistolas de alta viscosidad y 2 tubos de alta temperatura con bajada neumática o manual y cierre del molde sobre guías de 4 columnas con bajada en seguridad en Modo manual para montaje y centrado de moldes, carrera de avance del inyector sobre correderas regulables.

El SISTEMA DE PRENSA DE MOLDEO A DIE CASTING GM MELT 2T dispone de un control de proceso del ciclo productivo PLC con posibilidad de programar hasta 100 recetas memorizables para los tiempos de primera y segunda inyección, mantenimiento, refrigeración por aire y agua.

El SISTEMA DE PRENSA DE MOLDEO A DIE CASTING GM MELT 2T dispone de un fusor con control de temperatura en tres zonas (fusión - tubo - cabezal de inyección) con previsión de expulsión comoldeado.

Technical features:

| FUSOR ALIMENTATION | Triphase 380 V 50/60 Hz |

| COMMAND CONSOLE ALIMENTATION | Monophase 230 V 50/60 Hz |

| PNEUMATIC ALIMENTATION | 6÷8 Bar |

| FUSOR ABSORMENT | 4.400 W |

| CYCLE TIME | Programmable |

| CLOSING AND OPENING OF THE MOLD HOLDER | Manual |

| MOLD DIMENSIONS | Customizable |

| WORKABLE DIAMETERS | On Customer Request |

| PRODUCTIVITY | Depends |

| DISPLAY | Touch Screen LCD Liquid Cristal Display |

| MEMORY | 100 |

| WEIGHT | 240 Kg |

| DIMENSIONS | 2200x1200x2200 mm (WxDxH) |

IN ADDITION TO THE SALE OF THE EQUIPMENT GM AUTOMAZIONI IS ABLE TO PROVIDE MANY SERVICES, INCLUDING:

- WIDE RANGE OF PRODUCTS FROM OUR PRODUCTION AND THE BEST BRANDS ON THE MARKET

- CUSTOMIZATION OF EQUIPMENT AND PLANTS TAILORED TO THE CUSTOMER'S NEEDS

- DESIGN AND REALIZATION OF SPECIAL SYSTEMS

- TECHNICAL ASSISTANCE AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- SPARE PARTS FOR ALL MACHINES OFFERED

- COURSES AND DEMONSTRATIONS TO USE THE EQUIPMENT BETTER

- INSTALLATION AND TRAINING OF THE STAFF EMPLOYED BY THE MACHINES

- VERIFICATION OF FEASIBILITY ACCORDING TO CUSTOMER REQUESTS

- FREE SAMPLES BY TESTING DIRECTLY ON YOUR SAMPLES

- DEMONSTRATION OF THE EQUIPMENT AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- COURSES AND SEMINARS FOR IN-DEPTH INFORMATION ON THE USE OF EQUIPMENT

- SCHEDULED MAINTENANCE TO AVOID EXPENSIVE MACHINE STOP

- POSSIBILITY OF EXCHANGE: THE OLD SYSTEM CHANGES WITH A NEW AND MORE COMPETITIVE

- WE ARE SUPPLIERS OF STEEL, HARD METAL AND TITANIUM STRIPPING BLADES, MINI-APPLICATION CRIMPERS, ELECTRIC TERMINALS, PRE-INSULATED CONNECTORS, SPLICE STRIP

- WITHDRAWAL AND OVERVALUATION OF USED

- SALE OF COMPONENTS AND ACCESSORIES OF THE MAJOR BRANDS OPERATING ON THE MARKET

- POSSIBILITY TO IMPLEMENT OR MODIFY YOUR OLD PRODUCTION PLANT FOR YOUR NEW MARKET NEEDS