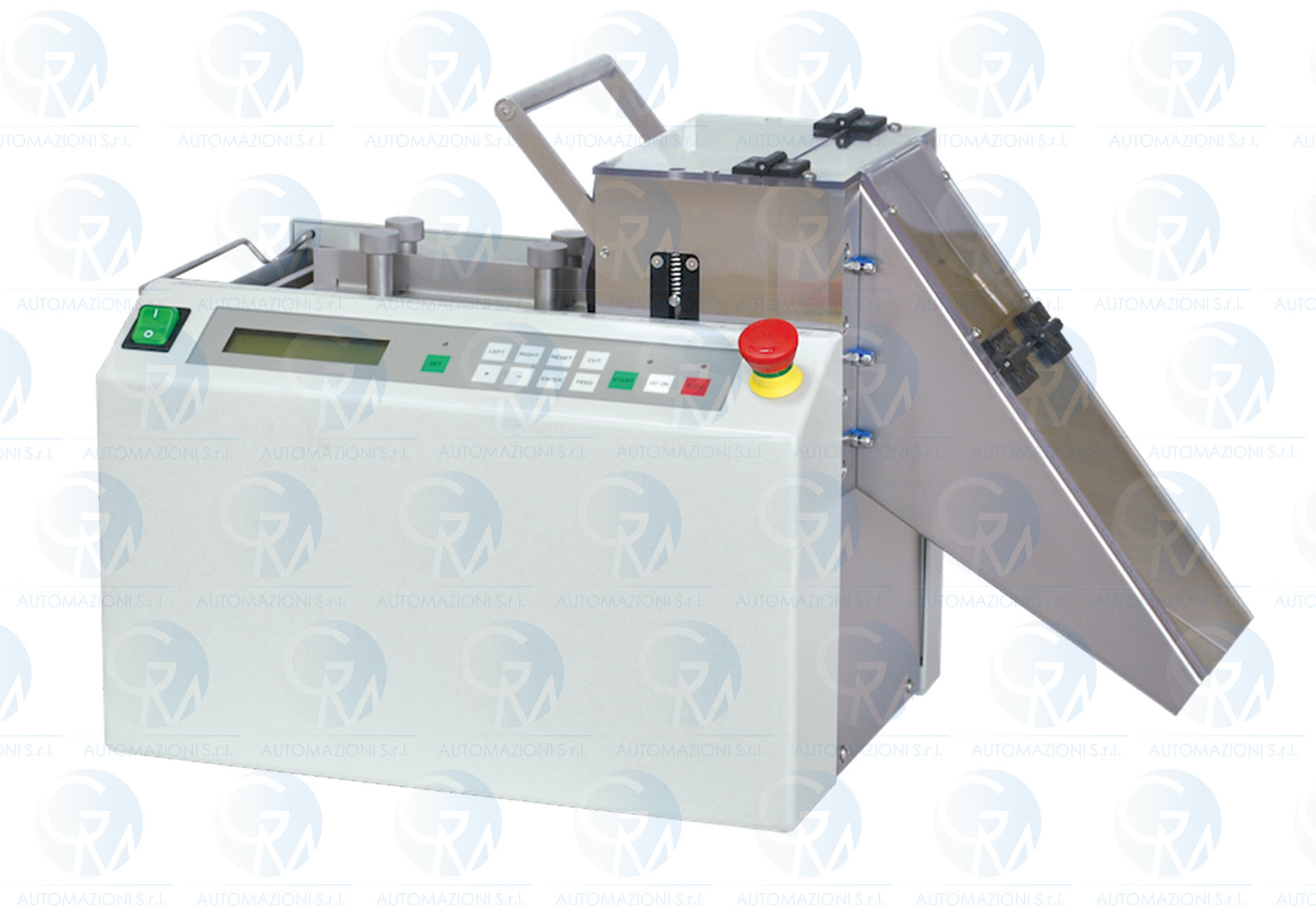

CUTTING MACHINE GM G100

English

Immagine:

The machine can be used by anyone without long training and the operating language can be set on the display.

The CUTTING MACHINE GM G100 is suitable not only in the field of processing of CABLES, but also in various applications in the field, no matter if it is plastic filaments for glasses, materials for grinding or rubber for clothing, this CUTTING MACHINE GM G100 it's always the right choice.

All drive parts and the entire cutting unit are made of high quality stainless steel. This guarantees a lasting operation.

Through the keyboard of the CUTTING MACHINE GM G100 you can set and modify the cut timing and the various engine speeds to maximize productivity or adapt them to production needs while maintaining a high level of quality of the processed product.

The CUTTING MACHINE GM G100 machine is CE marked and is equipped with safety devices, protections and accident prevention systems according to the regulations in force.

Workable products:

- UNIPOLAR CABLES

- MULTIPOLAR CABLES

- FLAT CABLES

- METALLIC CABLES

- THERMOR-EXTRINGENT SLEEVES

- PIPES

Technical features:

| DIMENSIONS | 350 x 260 x 250 mm (WxDxH) |

| WEIGHT | 35 Kg |

| ALIMENTATION | 110V to 230V / 50-60Hz |

| ABSORBMENT | 250W |

| CUTTING WIDTH | 100 mm max |

| CUTTING LENGTH | Da 1 mm a 100 m |

| CUTTING HEIGHT | Till a 12 mm |

| WORKABLE SECTION | Till a 16 mm2 |

IN ADDITION TO THE SALE OF THE EQUIPMENT GM AUTOMAZIONI IS ABLE TO PROVIDE MANY SERVICES, INCLUDING:

- WIDE RANGE OF PRODUCTS FROM OUR PRODUCTION AND THE BEST BRANDS ON THE MARKET

- CUSTOMIZATION OF EQUIPMENT AND PLANTS TAILORED TO THE CUSTOMER'S NEEDS

- DESIGN AND REALIZATION OF SPECIAL SYSTEMS

- TECHNICAL ASSISTANCE AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- SPARE PARTS FOR ALL MACHINES OFFERED

- COURSES AND DEMONSTRATIONS TO USE THE EQUIPMENT BETTER

- INSTALLATION AND TRAINING OF THE STAFF EMPLOYED BY THE MACHINES

- VERIFICATION OF FEASIBILITY ACCORDING TO CUSTOMER REQUESTS

- FREE SAMPLES BY TESTING DIRECTLY ON YOUR SAMPLES

- DEMONSTRATION OF THE EQUIPMENT AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- COURSES AND SEMINARS FOR IN-DEPTH INFORMATION ON THE USE OF EQUIPMENT

- SCHEDULED MAINTENANCE TO AVOID EXPENSIVE MACHINE STOP

- POSSIBILITY OF EXCHANGE: THE OLD SYSTEM CHANGES WITH A NEW AND MORE COMPETITIVE

- WE ARE SUPPLIERS OF STEEL, HARD METAL AND TITANIUM STRIPPING BLADES, MINI-APPLICATION CRIMPERS, ELECTRIC TERMINALS, PRE-INSULATED CONNECTORS, SPLICE STRIP

- WITHDRAWAL AND OVERVALUATION OF USED

- SALE OF COMPONENTS AND ACCESSORIES OF THE MAJOR BRANDS OPERATING ON THE MARKET

- POSSIBILITY TO IMPLEMENT OR MODIFY YOUR OLD PRODUCTION PLANT FOR YOUR NEW MARKET NEEDS

Categoria prodotto: